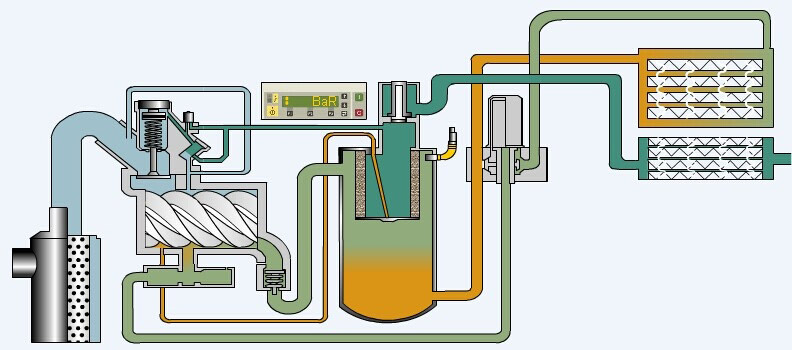

The working process of the screw air compressor is divided into six steps as shown in the figure below, mainly to help you better understand the working principle of the screw air compressor:

Working process diagram of screw air compressor

The first step is that the air compressor sucks the surrounding air through the air filter to make it enter the compressor host.

The second step is to change the volume of the speech machine through the joint movement of the yin and yang rotors. At the same time, the chamber continuously sprays oil to lubricate and cool the screw. The heated oil gas mixture is thus produced.

Step 3: The oil and gas mixture after temperature and pressure rise enters the oil and gas separator tank through the exhaust check valve.

Step 4: Most of the oil in the main engine chamber is separated from the compressed air in the oil-gas separator, and then returned to the machine for recycling after cooling.

Step 5: once the air in the oil-gas separator reaches the required minimum pressure, the minimum pressure valve will open; High temperature compressed air enters the aftercooler.

Step 6: The temperature of the compressed air is cooled down in the aftercooler to get the compressed air you need.